WELCOME TO BUISARD, FRENCH CONCEPTOR AND DESIGNER

3 TYPES OF CABS

Buisard adapts its industrial response to the needs of each of its customers.

Some builders want their cabs delivered in bare bones condition (structure + windows) so they can outfit them on their own assembly lines.

Others want partially equipped cabs. For them, we deliver cabs with all standard accessories, and they carry out finishes and customizations on their own lines.

For plug and play cabs, builders choose to entrust us with the manufacturing, logistics and complete customization of their cabs. We deliver 100% equipped cabs, ready to be mounted on their vehicles.

Regardless of our customer’s choice, all the products we deliver are given the same attention and care from our teams.

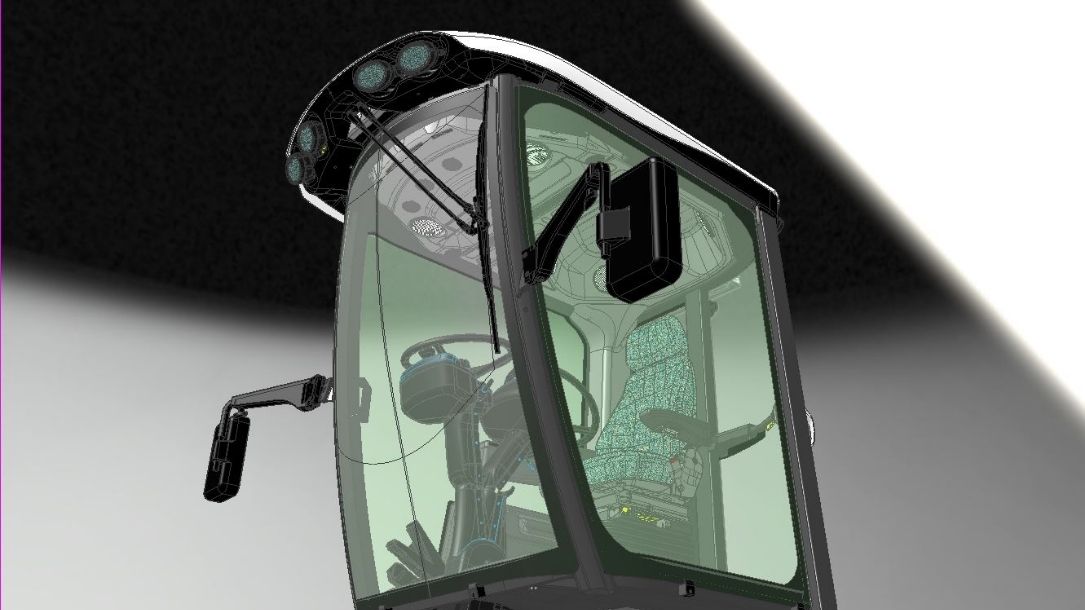

Using our customers’ specifications, our designers plan and draw the 3D model of our cabs. This design work is performed in close collaboration with our methods technicians to ensure the cab designs are compatible with our production facilities. Once the design is done, our teams develop the specific tools necessary and have them manufactured. They also prepare manufacturing data sheets that will be deployed in our four cab manufacturing workshops.

Our cabs are designed to resist approved roll-over and falling object protection with ROPS (Roll-Over Protective Structure) ;

FOPS (Falling-Object Protective Structure).

Do you know?

The first sheet metal farm tractor cab was manufactured in 1959. From 1959 to 1995, 400,000 sheet-metal cabs were sold throughout Europe.

The roll bar appeared in the 1960’s. BUISARD organized demonstrations of roll-overs with professional stunt men, in order to raise the awareness of users for their safety. Legislation introduced in 1976 made roll bars mandatory.

Max BUISARD received the Gold Medal from the French Agricultural Academy in 1992 for his innovations and creations in the field of safety and comfort.

We develop products and their industrialization to meet the needs of our customers, ranging from 100 to 10,000 cabs a year.

Small annual quantities

20 to 200 per year

Philosophy

Tool simplicity

Manual fabrication

Average annual quantities

300 to 4500/year

Philosophy

Mix of manual/robotics

Flexible manufacturing methods

High quantities annually

of 5000 per year

Philosophy

Complex tools

robotic and/or dedicated manufacturing